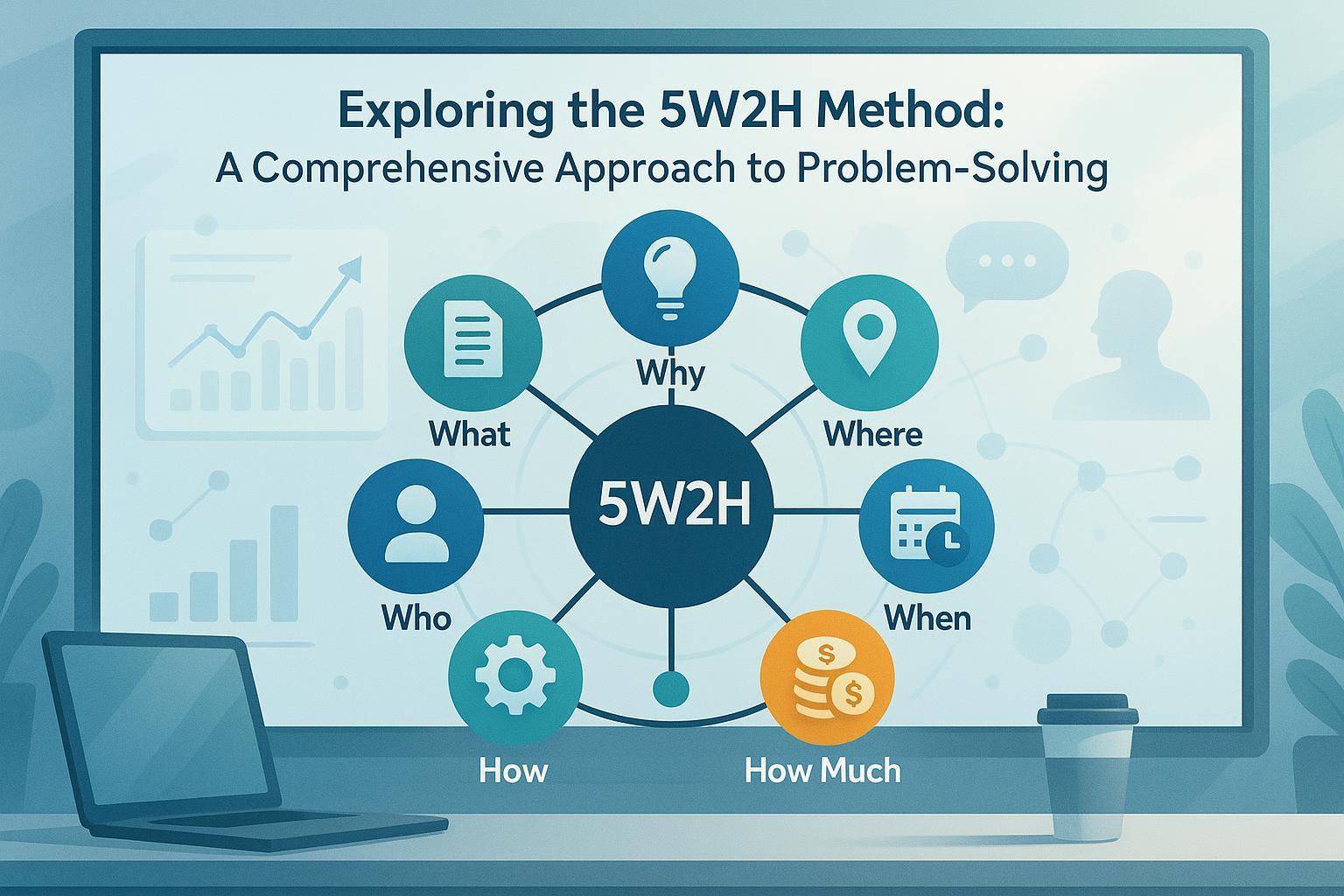

Exploring the 5W2H Method: A Comprehensive Approach to Problem-Solving

Introduction: Why the 5W2H Method Matters More Than Ever

In a world where complexity and speed define every business landscape, organizations and professionals are perpetually challenged to find robust, repeatable methods for solving problems. Enter the 5W2H method—a universal framework for analytical clarity, cross-team alignment, and actionable results. Whether you’re a seasoned manager, an operational team leader, or a student of process improvement, mastering 5W2H is a cornerstone for strategic, data-driven decision-making.

This ultimate guide provides a reference-grade, sector-spanning resource on 5W2H. You’ll discover not just the what and why, but step-by-step instruction, case studies across industries, downloadable templates, common pitfalls, advanced integrations, and visual tools—making this the go-to roadmap for problem solvers who demand more than generic tips.

Table of Contents

- What is the 5W2H Method? Origin, Purpose & Universal Relevance

- Deep Dive: Breakdown of Each 5W2H Element

- What

- Why

- Where

- When

- Who

- How

- How Much/How Many

- Step-by-Step: Implementing 5W2H in Practice

- Case Studies: Multi-Industry Real-World Applications

- Common Pitfalls and Best Practices

- 5W2H vs. Other Problem-Solving Frameworks

- Downloadable Templates, Resources, and Further Reading

- Conclusion: Next Steps and Actionable Takeaways

1. What is the 5W2H Method? Origin, Purpose & Universal Relevance

The 5W2H method is a structured analytic tool designed to solve problems by rigorously answering seven essential questions: What, Why, Where, When, Who, How, and How Much/How Many. Its simple but powerful approach ensures teams fully define issues before proposing solutions, making it the backbone of Lean, Six Sigma, and modern management.

Origins and Evolution

- Concept origins: Attributed to Sakichi Toyoda in Japan (Toyota Production System), adapted from investigative journalism’s “Five Ws.”

- First widespread use: Japanese quality management and Lean Manufacturing (late 20th century).

- Current dominance: Embedded in manufacturing, healthcare, IT, and quality management globally.

"5W2H enforces fact-based thinking before action—a prerequisite for any sustainable improvement process." — Jeffrey Liker, "The Toyota Way"

Core Principles

The essence of 5W2H lies in systematic, holistic questioning:

- What: What is the problem?

- Why: Why does it occur?

- Where: Where is it located or manifesting?

- When: When does it happen?

- Who: Who is involved or affected?

- How: How does it occur/process mechanics?

- How much/many: What’s the quantifiable impact? Each question ensures all relevant dimensions are addressed before jumping to solutions.

Universal Use-Case Spectrum

5W2H underpins problem-solving in:

- Lean/Six Sigma projects

- CAPA (Corrective and Preventive Action) in life sciences

- Incident response in IT/devops

- Customer complaints and support escalation

- Healthcare process improvement

- Project onboarding and risk analysis

2. Deep Dive: Breakdown of Each 5W2H Element

Understanding each question’s strategic significance can be the difference between clarity and confusion. Here’s a granular analysis with pro insights and sector-ready prompts.

What: Defining the Problem Clearly

- Purpose: Establishes factual baseline—avoids vague or symptomatic focus.

- Examples: Equipment downtime, delayed project delivery, patient readmissions.

- Tip: Use measurable terms. E.g., “Absenteeism rose 15% Q2 vs Q1.”

Why: Uncovering the Underlying Cause

- Purpose: Prevents treating symptoms; direct path to root cause.

- Examples: Machine maintenance skipped; shifts understaffed; unclear instructions.

- Tool Integration: Often paired with “5 Whys” for deeper drill-down.

Where: Identifying the Location or Context

- Purpose: Pinpoints where, spatially or organizationally, the issue occurs.

- Examples: Logistic center A; emergency room admissions; customer support for Europe region.

- Tip: Map with visual tools (see Miro 5W2H templates).

When: Timing and Sequence

- Purpose: Exposes patterns, recurrence, and peak risk windows.

- Examples: Monday mornings; Q4 releases; pre-shift handovers.

- Metric: Timeline charts are powerful here (e.g., Gantt/Run charts).

Who: Stakeholders and Participants

- Purpose: Defines responsibility, impact, and influence.

- Examples: Assembly team B; project managers; external vendors.

- Pro tip: Assign clear action owners at this stage.

How: Mechanics or Processes Involved

- Purpose: Shows step-by-step sequence or workflow triggering the problem.

- Examples: Paper forms routing, medication dispensing protocol, app deployment pipeline.

- Resource: Visual process mapping recommended (flowcharts, Swimlane diagrams).

How Much/How Many: Quantifying the Impact

- Purpose: Forces objectivity—size, cost, risk, or volume.

- Examples: $60,000 lost revenue, 30% overrun, 8 patients affected/month.

- Tip: Set baselines for measuring improvement.

3. Step-by-Step: Implementing 5W2H in Practice

A. Prepare for Analysis

- Identify the problem area and gather relevant data.

- Form a multidisciplinary team.

- Select a digital template (Excel, Google Sheets, Notion 5W2H, etc.).

B. Conduct the 5W2H Analysis

- Facilitated Workshop: Schedule a collaborative session—on-site or via Miro/Teams/Zoom.

- Guided Walkthrough:

- Document the clear “What.”

- Brainstorm “Why”—use supporting data.

- Map “Where”—location or process context.

- Pinpoint “When”—draw a timeline if possible.

- Identify “Who”—include direct and peripheral roles.

- Detail “How”—stepwise, process or workflow.

- Quantify “How Much/Many”—numbers, costs, metrics.

C. Prioritize and Plan Actions

- Review all responses for gaps and assumptions.

- Assign owners to each action step.

- Use color codes or priorities (templates in next section).

D. Monitor and Iterate

- Track KPIs linked to actions (e.g., error frequency, turnaround time).

- Return to 5W2H for periodic reviews (PDCA cycles).

Downloadable Template: 5W2H Template for Excel/Sheets (via SlideKit) | Miro Interactive Whiteboard Template

4. Case Studies: Multi-Industry Real-World Applications

Manufacturing: Reducing Assembly Line Downtime

- What: Frequent line stoppages on Assembly Line C

- Why: Sensor misalignment causes false emergency stops

- Where: Station 5 conveyor junction

- When: Post-maintenance restarts, Mondays/Fridays

- Who: Maintenance technicians, shift managers

- How: Routine maintenance steps missed reset calibration

- How Much: 16 stops/month, $45,000 monthly loss Result: Process mapped, retrained, downtime cut by 18% in 6 months (iSixSigma Case)

Healthcare: Streamlining Preoperative Fasting

- What: Patients overly fast before surgery

- Why: Generic instructions not tailored to surgery time

- Where: Surgical admissions, all hospital units

- When: Every preoperative day

- Who: Admitting nurses, anesthesiologists

- How: Standardized forms, no time customization

- How Much: ~2 hours excess fasting per patient, increased dehydration complaints Result: Custom templates reduced unnecessary fasting, improved patient satisfaction, complaints fell 40% (PMC/NCBI 2025)

IT/Software: Faster Incident Response

- What: Prolonged resolution of major incidents

- Why: Unclear handoffs between teams

- Where: DevOps/Support transition points

- When: High-traffic deployments, weekends

- Who: On-call engineers, support leads

- How: Email escalations, manual triage

- How Much: 3x longer MTTR vs. SLA, user churn Result: 5W2H adoption standardized triage/upskilling, MTTR dropped 28% in 2 quarters (Techiequality)

Education & Public Sector: Reducing Student Absenteeism

- What: Absentee rates above target

- Why: Pattern of disengagement, transport issues

- Where: Primary campuses in rural zip codes

- When: Mondays and exam weeks

- Who: At-risk student cohorts, bus drivers, parents

- How: Manual attendance, inconsistent follow-up

- How Much: 12% absentee rate (>5% target) Result: Transport support, automated alerts, absenteeism halved in one year (Case Reference: LeadingBusinessImprovement.com)

5. Common Pitfalls and Best Practices

Common Pitfalls

- Superficial Answers: Rushing or guessing leads to poor insights.

- Incomplete coverage: Missing one or more questions.

- Symptom, not Root Focus: Stopping analysis at surface signs without fact-checking causes.

- Lack of Quantification: Skipping "How Much"/"How Many" leads to fuzzy targets.

- Isolated Completion: Not involving diverse stakeholders reduces relevance and follow-through.

- Not Updating: 5W2H is static, even as the situation evolves.

Best Practices

- Always fact-check and require data-backed responses.

- Use collaborative whiteboards or digital tools for input and visibility.

- Assign owners and deadlines—track actions post-analysis.

- Integrate periodic 5W2H review in project cycles (supports PDCA and Lean control).

- Pair with complementary tools (Fishbone, 5 Whys) for layered analysis.

- Make use of visual infographics and process maps.

6. 5W2H vs. Other Problem-Solving Frameworks

| Criteria | 5W2H | 5 Whys | Fishbone (Ishikawa) | PDCA |

|---|---|---|---|---|

| Purpose | Full-spectrum issue definition | Root cause drill-down | Multi-factor root mapping | Iterative improvement cycle |

| Scope | Universal—Who, What, Why, Where, When, How, How Much | "Why" only | People, Process, Machine, Materials, etc. | Plan-Do-Check-Act (cycle) |

| Output | Structured, holistic action plan | Root cause(s) | Visual cause/effect | Action, measurement, check-feedback |

| Strength | Cross-functional clarity & buy-in | Depth for single root cause | Visually diagnostic for complex issues | Drives continuous improvement |

| Weakness | May lack depth unless coupled with other methods | Does not scope full issue | Can get unwieldy, time-consuming | Needs strong scoping upfront |

Expert Consensus: 5W2H is recommended as the initial scoping and action-filtration tool, especially before launching root cause analyses or iterative cycles.

7. Downloadable Templates, Resources, and Further Reading

- Downloadable Templates:

- Exclusive Advanced Guides

- Further Reading:

Frequently Asked Questions (FAQ)

Q: Can 5W2H be used outside of manufacturing? A: Absolutely—5W2H is widely adaptable for healthcare, IT, education, public sector, startups, and service industries. Its versatility is one of its greatest strengths.

Q: How is 5W2H different from the 5 Whys? A: The 5 Whys focuses solely on root cause, while 5W2H provides a full-scope problem definition, covering broader context, stakeholders, timelines, and impact.

Q: Should we always use all seven questions? A: For major or complex issues—yes, for completeness. For smaller or routine matters, prioritize the most relevant ones but don’t omit quantification (“How Much”).

Q: What if the answers are uncertain or qualitative? A: Start with available data or observations, then design simple measurements or pilot tests to quantify where possible. Return to update as evidence emerges.

Conclusion: Your Blueprint for Structured Success

Mastering the 5W2H method converts confusion into clarity and inertia into action. By adopting this comprehensive, systematically-proven approach, you build a strong foundation for repeatable problem-solving, stakeholder alignment, and performance improvement—across all industries and team structures.

“A problem well-stated is a problem half-solved.” — Charles Kettering

Ready to start? Download a 5W2H template now, bring your team together, and use the framework as both an onboarding tool and a troubleshooting engine. For advanced integration and training resources, consult the links above.

Ultimate 5W2H Guide: Quick Reference Checklist

- [ ] Define the problem with “What”—data first, not assumptions

- [ ] Pursue “Why” until facts align (use 5 Whys as needed)

- [ ] Identify all locations, contexts (“Where”), and affected areas

- [ ] Establish precise timing/sequence with “When” (timeline mapping)

- [ ] List all involved roles (“Who”), assign action owners

- [ ] Map the process (“How”)—steps, breakdowns, or visuals

- [ ] Measure “How Much/How Many” for quantifiable impact

- [ ] Use collaborative templates: Excel, Notion, Miro, PDF

- [ ] Review, action-plan, and return for PDCA improvement

This guide is continuously updated with new case studies and digital best practices. Share your feedback or success story to help enhance 5W2H adoption across industries.